notes

Examples of slow data streams.

- bicycle wheel sensor that triggers once per rotation

- The data stream from an OBD-II scanner which can only be polled every 300ms or slower

- a traffic sensor on a quiet street

There aren’t enough data points to use typically smoothing methods like moving average or logarithmic smoothing. Here are 2 ideas for increasing data points using repetition:

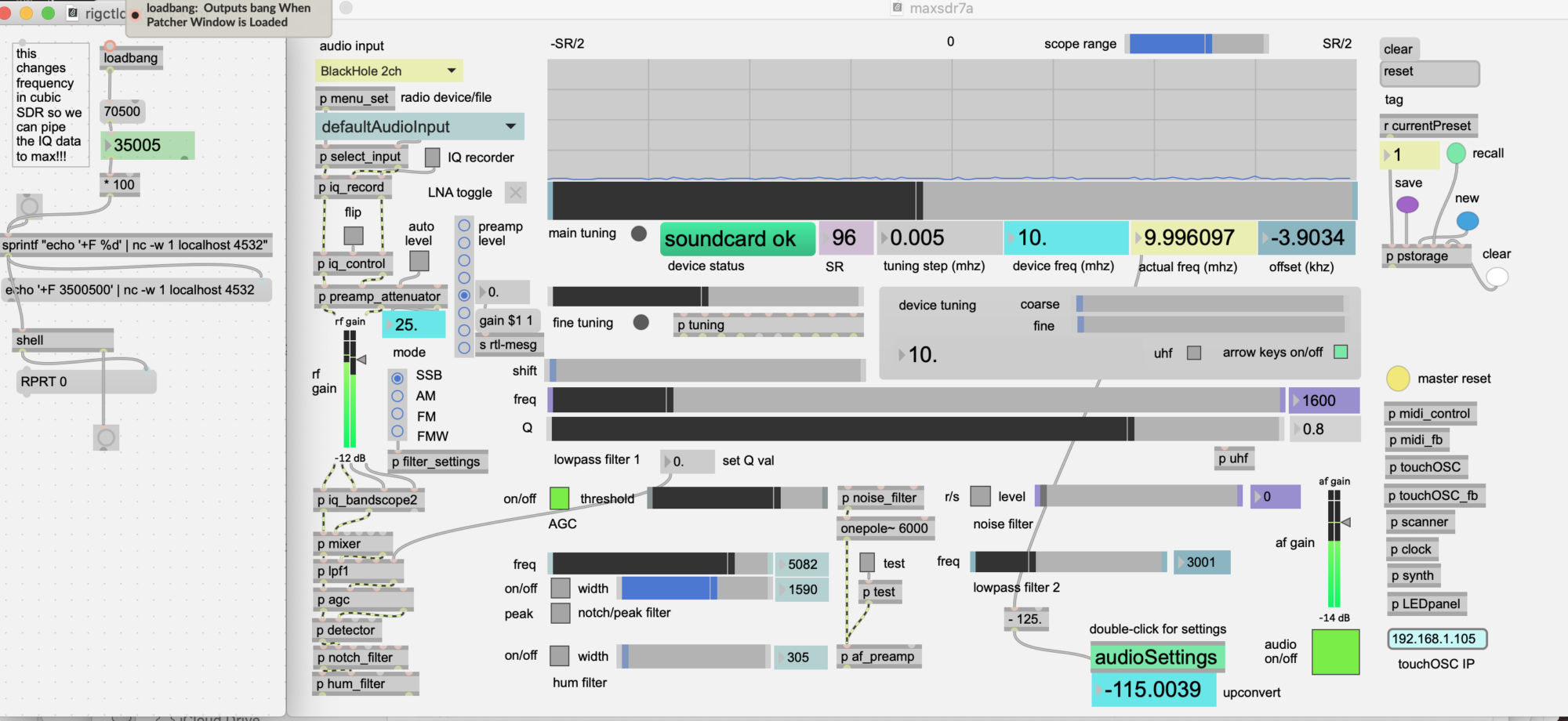

- feed the data into the right inlet of an [f] object to set its value. The left inlet receives the output of a [metro] set at the desired stream rate. Then the output of the [f] object can be smoothed using conventional methods.

- convert data to a signal using [sig~] then smooth using [slider~] or [rampsmooth~] then convert back to float using the right outlet of [number~]